How To Repair Deep Scratches In Pontoon Boat

Gelcoat Scratch Repair

Surface scratches can be buffed out of gelcoat with polishing compound, but deep scratches must be filled. When the gelcoat surrounding a scratch is in good status, the filler of option is gelcoat paste, which provides both filler and terminate in a unmarried application — but non a single step. Because the surface of the cured paste volition be uneven, sanding and polishing are required to smooth the repair and blend it with the rest of the hull. Except for colour matching, gelcoat repairs are like shooting fish in a barrel and straightforward.

Gelcoat Choices

Y'all will find gelcoat available every bit both a resin and in a thicker putty form called paste. For scratch repair you want paste. Repair kits comprised of a pocket-size corporeality of gelcoat paste and hardener, a selection of pigments, mixing sticks, and sealing film can exist purchased for less than $20. Purchase a flexible plastic spreader if you don't already have one. Yous volition also need sheets of 150-, 220-, 400-, and 600-grit wet-or-dry sandpaper. A single sheet of each will be more than ample to fair all the paste in a repair kit.

Color Matching

The hardest function of a repair to the surface of a fiberglass gunkhole is matching the color. Professionals who do gelcoat repairs daily still have difficulty getting a perfect match. Even "factory" colors don't match exactly after a gunkhole has been in the sun for a few years.

White has the pregnant advantage of beingness fairly piece of cake to lucifer, and once a small repair is buffed out to a gloss, shading differences will be unnoticeable. Matching colored hulls is somewhat more than challenging.

A color-sample carte from your local paint store that matches your hull can provide valuable help. Enquire the store clerk the formula; they custom-mix the color by adding tints to a white base. The formula may call for a half-dozen dissimilar tints, only the important ones are those specified in the largest quantities. Y'all can use the tints in your repair kit to judge the formula.

Always color gelcoat paste earlier you add together the catalyst. Put exactly one ounce of paste into a mixing loving cup and add the tints a drop at a time. Go on track of the number of drops of each tint. When the color looks shut in the loving cup, bear upon a driblet of the mix onto the hull. Make needed adjustments until you are satisfied with the match — don't look perfection — then write down the formula and so you can duplicate it for the rest of the paste.

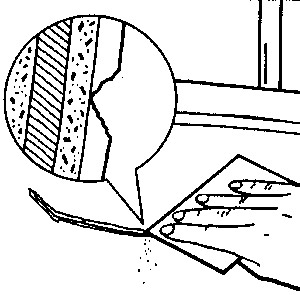

Preparing the Scratch

Never try to repair a scratch by simply painting over it with gelcoat. Gelcoat resin is too thin to fill a scratch and gelcoat paste is too thick. Instead of penetrating scratches, gelcoat paste will span them, leaving a void in the repair. To become a permanent repair, draw the corner of a scraper or screwdriver downwardly the scratch to open it into a wide V.

Catalyzing

Catalyzing Polyester Resin

The hardener for gelcoat is the aforementioned equally for any polyester resin — methyl ethyl ketone peroxide, or MEKP. Gelcoat resin usually requires i to 2 percent of hardener past volume (follow the manufacturer'southward instructions). As a general rule, four drops of hardener will catalyze i ounce of resin at 1 percent. The mix shouldn't kick (start to harden) in less than thirty minutes. Hardening in about two hours is probably ideal. Always err on the side of also little hardener. Also be certain to stir in the hardener thoroughly; if you lot fail to catalyze every bit of the resin, parts of the repair will exist undercured.

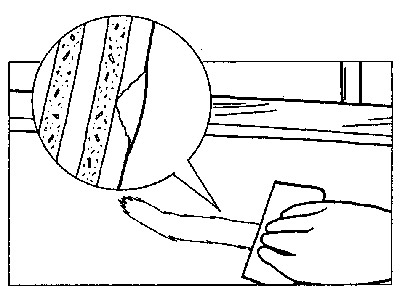

Spreading Gelcoat Paste

Spreading Gelcoat Paste

Work the gelcoat paste into the scratch with a flexible plastic spreader. Let the putty bulge a little behind the spreader; polyester resin shrinks slightly as information technology cures, and you're going to sand the patch anyhow. Just don't let information technology burl as well much or you'll brand extra work for yourself.

Scrape up any excess paste across the patch area.

Covering the Repair

Gelcoat will not fully cure in air. To seal the surface of a scratch repair, embrace it with a canvas of plastic film. The kit may include sealing moving picture. Otherwise a department of kitchen "zipper" pocketbook works especially well considering it tends to remain smooth and the gelcoat volition not adhere to it. Tape i edge of the plastic to the surface just beyond the repair, and then polish the plastic onto the gelcoat and record downwardly the remaining sides.

Sanding and Polishing

Sanding and Polishing

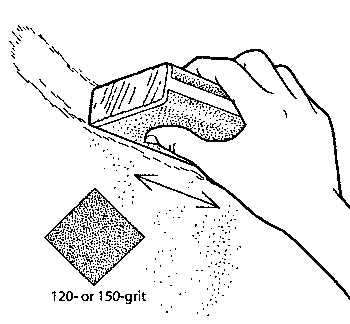

After 24 hours, peel away the plastic. The amount of sanding required will depend on how smoothly you applied the gelcoat.

A 5 1/2-inch length of 1 x two makes a convenient sanding block for a scratch repair. Wrap the block with a quarter sheet of 150-dust paper. Utilize the edge of the block to confine your sanding to the new gelcoat. Use brusk strokes, taking intendance that the paper is sanding only the patch and not the surrounding surface. Never exercise this initial sanding without a block bankroll the paper.

When the new gelcoat is affluent, put 220-grit wet-or-dry paper on your cake and moisture sand the repair, this time with your block flat. Use a circular movement and go on a trickle of water running on the sanding expanse. Plume the repair into the old gelcoat until your fingertips cannot detect a ridge. If the hull is curved, take intendance non to sand the repair flat.

Abandon the block and switch to 400-grit wet-or-dry out paper. Moisture sand the surface until the repair area has a uniform advent. Follow this with 600-grit wet-or dry. Wear fabric garden gloves — the kind with the hard dots — to salve the tips of your fingers.

Dry the surface area and use rubbing compound to give the gelcoat a high gloss. Swirl a soft, folded cloth over the surface of the compound to load the textile, then rub the compound onto the repair area. Buff it with a circular motion, using heavy pressure initially, then progressively reduce the pressure until the surface becomes glassy. If the gelcoat shows swirl marks, buff them out with a very fine finishing chemical compound.

End the job past giving the repair area a fresh coat of wax. If your color lucifer is reasonably good, the repair will be virtually undetectable.

Author

Don Casey

Correspondent, BoatUS Mag

Don Casey has been 1 of the most consulted experts on boat care and upgrades for 30 years, and is one of the BoatUS Magazine's console of experts. He and his wife cruise aboard their thirty-footer function of the year in the eastern Caribbean. His books include Don Casey's Complete Illustrated Sailboat Maintenance Transmission, and the recently updated This Old Boat, the bible for exercise-it-yourself boaters.

BoatUS Magazine Is A Do good Of BoatUS Membership

Membership Benefits Include:

-

Subscription to the print version of BoatUS Magazine

-

four% back on purchases from Due west Marine stores or online at WestMarine.com

-

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

-

Deals on cruises, charters, car rentals, hotel stays and more…

-

All for only $25/twelvemonth!

Source: https://www.boatus.com/expert-advice/expert-advice-archive/2012/july/gelcoat-scratch-repair

Posted by: goldmanreaver.blogspot.com

0 Response to "How To Repair Deep Scratches In Pontoon Boat"

Post a Comment